- Sku: G3000

- Vendor: Ulster Ceramics Pottery Supplies

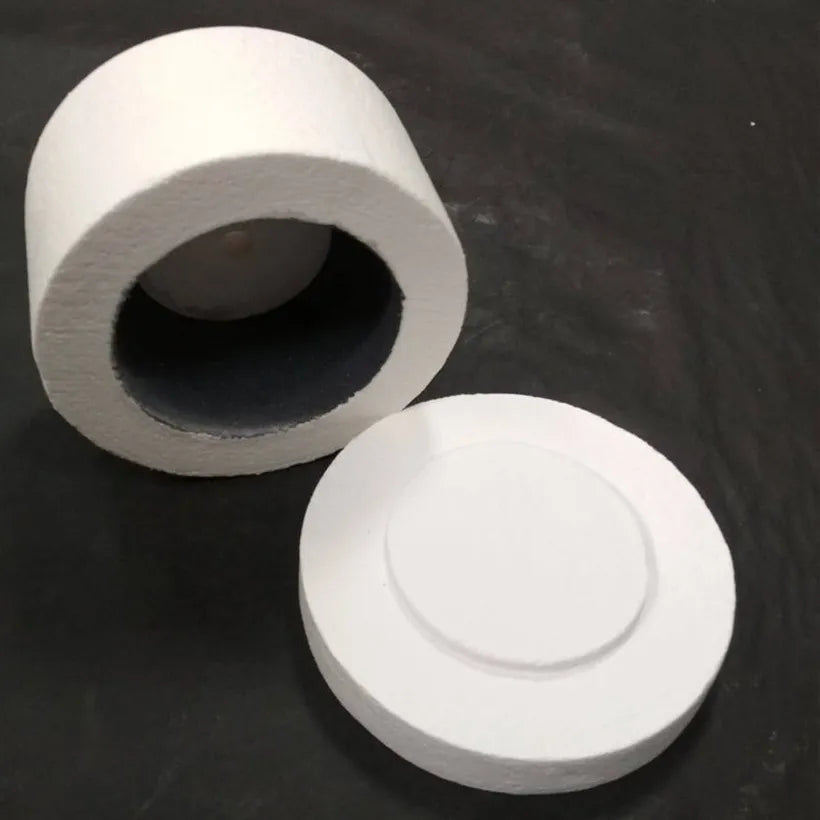

MiNi Glass Kiln 120MM

Code G3000

120MM external diameter 75MM internal diameter

This could be a mini revolution in glass working. This device works in most household microwaves and can fuse glass in around 4 – 6 minutes. Simply line the chamber with Papyros paper, to prevent sticking, assemble your pieces of fusing glass (make sure they are compatible!) and switch on at full power.

Allow to cool thoroughly before opening to see the results!

Designed for jewellery pieces or small test firings, the microwave kiln makes glass fusing accesible to anyone for a relatively small investment. Can also be used for PMC art clays, enamelling and clay.

3″ Internal chamber.

How it works

A material is heated from the outside in a conventional kiln. Microwave firing can shorten the firing period because the material itself generates the heat by microwaves and does not need to waste heat transfer energy in travelling from the outside.

In microwave firing, the surface temperature may lower than the inside. this problem is solved by introducing special lining materials as a self-consistent isothermal barrier which keeps the microwave energy and heat inside the kiln resulting in a rapid rise in temperature. Therefore, glass can be fired much more uniformly by heating them internally and externally.

TIPS: When using the microwave kiln, it is important to remember to be safe. The glass inside the kiln can reach 900 degrees celcius, so take extreme caution when fusing.

We recommend that you always wear eye protection and heat proof gloves. Have a heatproof surface to work on. We also recommend separate microwaves for glass work and for food use. Using the kiln requires a little trial and error to achieve your desired result, so keep a log of glass used, the thickness, timings etc to refer back to as your ‘recipe book’.

It is important to use fusing glass only in the kiln. You cannot mix different types of glass unless they are compatible.

You must line the kiln with Papyros paper,which must be hoovered out after every use.. It is available from us in sheets or on a roll. This paper stops the molten glass sticking to the kiln base, which can damage it.

When using the kiln, it is possible to check the progress of the firing (provided you don’t open the kiln for too long, letting cold air in can cause cracking), you can peep inside (taking care as it is very hot and will be glowing red) to see how well the glass is rounding off. It is a good idea to try a shorter (6 minute firing in 6” kiln or 3 minute firing in 3” kiln) first to assess how efficient your microwave is at heating the kiln.

You can check the glass and then fire for a extra minute at a time to work out the length of time needed. Over firing will cause the glass to spread out and possible stick to the base / sides of your kiln and damage it. This can also happen if your glass is piled too high. A stack totalling 6mm thickness will not spread too much, and is best, although thicker can be used if kept away from the edges.

EXAMPLE: To fire a pendant with a hole through the middle, sandwich a piece of Papyros paper (rolled up tightly) between two layers of glass and follow our firing recipe: (based on 6” kiln in 750W microwave: reduce times if using a higher wattage microwave. And reduce times by half for 3” kiln)

Fire for 8 minutes on full power – check inside (fibre will look black). Fire for a further 1 minute – check inside (it should be glowing). Fire for a further 1 minute – check again to see how rounded the glass is.

Repeat in one minute bursts until you achieve the desired finish.

This is based on using bullseye glass, and was a small pendant, so may vary to your own sizes used. Firing for a shorter time will leave a textured finish, longer firings will round off the edges.

MiNi Glass Kiln 120MM

ULSTER CERAMICS SERVICING